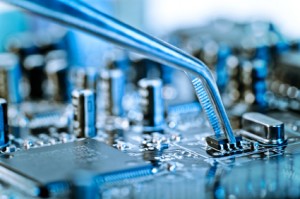

Printed Circuit Board

ImageTek Mfg. is a Valued Partner for PCB Solutions

We pride ourselves in flexible assembly processes that accommodate a wide range of printed circuit board applications. From low to high volume production, manual to automated assembly on both single and double-sided boards, we have a wide range of capabilities that ensure the production of quality assemblies. ImageTek Mfg. has been meeting the most stringent of PCB specifications, quickly and cost effectively, for 20 years and we continue to be a valued partner to many of New England’s leading OEM’s. ImageTek Mfg. delivers superior PCB Assembly through manufacturing traceability, quality control, and extensive testing.

We pride ourselves in flexible assembly processes that accommodate a wide range of printed circuit board applications. From low to high volume production, manual to automated assembly on both single and double-sided boards, we have a wide range of capabilities that ensure the production of quality assemblies. ImageTek Mfg. has been meeting the most stringent of PCB specifications, quickly and cost effectively, for 20 years and we continue to be a valued partner to many of New England’s leading OEM’s. ImageTek Mfg. delivers superior PCB Assembly through manufacturing traceability, quality control, and extensive testing.

We ensure top quality through the use of computerized Automated Test Equipment (ATE) and detailed QA Lab analysis. We work closely with our customers to develop manufacturing processes appropriate to their needs and build functional testing equipment that will ensure that your product is made to your specifications — the first time and every time.

Our assembly capabilities include unique component sourcing to manual and automated placement of surface mount (SMT) components, down to 0201 sizes.

Our high speed SMT placement is accomplished utilizing two JUKI KE-Series modular assembly systems that ensure high output with maximum accuracy. These machines are tooled for rapid changeovers to guarantee that your production requirements are met.

Our Mirtec MV-2HT Series Desktop AOI Machine provides us with unsurpassed defect detection. We have three “cut & clinch” machines to accommodate thru hole and mixed technology boards and both leaded and lead-free wave solder capabilities. Lastly, we have two conformal coating machines that seal the PCB, protecting it from moisture, chemicals and corrosion.

Capabilities:

- Surface Mount (SMT)

- Through Hole (T/H)

- Prototypes / Beta Runs

- Turnkey or Consignment

- Chip Programming

- AOI Visual Testing

- ISO 9001:2015

- IPC 610 Class II